Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control

Why Every Fibre Optic Manufacturer Needs an Optical Fibre Diameter Analyser for Quality Control

Blog Article

How an Optical Fibre Diameter Analyser Enhances High Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing procedures represents a significant improvement in top quality control methodologies. By supplying real-time, specific measurements of Fibre diameters, this modern technology deals with the critical requirement for uniformity in production standards. With its ability to swiftly identify discrepancies and prompt restorative actions, the analyser not just enhances product reliability but likewise adds to general operational effectiveness. As industries increasingly focus on top quality and conformity, understanding the full effect of such advancements becomes important. What implications could this have for the future of Fibre manufacturing?

Relevance of Fibre Diameter Dimension

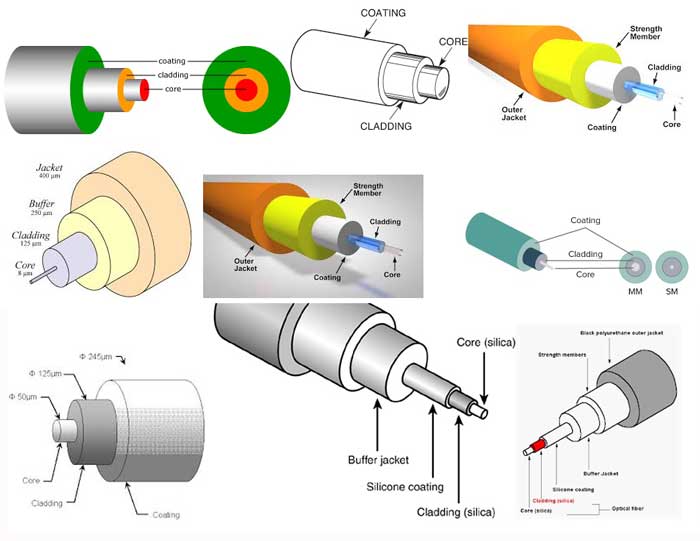

Precise measurement of Fibre Diameter is essential in the area of optical Fibre innovation, as it straight influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and total transmission effectiveness. Accuracy in determining Fibre Diameter makes sure that the optical residential or commercial properties are preserved within defined tolerances, which is crucial for optimal signal stability.

Variants in Fibre Diameter can bring about enhanced losses as a result of spreading and modal dispersion, influencing the top quality of data transmission. In high-speed communication systems, such disparities can lead to significant destruction of signal top quality, leading to data errors and minimized performance. Regular Fibre Diameter is crucial for compatibility with connectors and splicing modern technologies, which are essential components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing greatly rely on exact Diameter measurements to guarantee compliance with industry criteria. By carrying out robust dimension techniques, producers can enhance product integrity, lessen waste, and boost total system performance. Therefore, the value of Fibre Diameter dimension can not be overemphasized, as it acts as a keystone in the advancement of optical Fibre innovation and its applications in modern-day interaction networks.

Just How the Analyser Functions

The efficient measurement of Fibre Diameter counts on innovative logical techniques that make sure precision and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture processing algorithms to properly evaluate the Diameter of fibres as they are generated

Originally, a laser beam is guided at the relocating Fibre, producing a cross-sectional darkness. The analyser catches this shadow utilizing high-resolution electronic cameras positioned purposefully along the production line. The caught photos are after that refined in real-time to determine the Fibre's Diameter with exceptional precision.

The system uses innovative formulas that account for numerous factors, including variations in light intensity and ecological conditions, to enhance measurement integrity. It can detect minute adjustments in Diameter, such as changes that may occur throughout the production procedure.

In addition, the analyser can dealing with several fibres at the same time, increasing throughput without compromising precision. By giving instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a crucial role in maintaining stringent quality assurance standards, ensuring that the end product meets industry requirements and client requirements.

Benefits of Real-Time Monitoring

While traditional approaches of keeping track of Fibre Diameter frequently entail lengthy post-production checks, real-time monitoring significantly enhances the performance and top quality of optical Fibre production. optical fibre diameter analyser. This positive method allows manufacturers to recognize discrepancies in Fibre Diameter as they take place, rather than waiting until manufacturing is complete to examine top quality

By continuously determining the Diameter throughout manufacturing, manufacturers can guarantee that the fibres meet stringent specifications, leading to minimized irregularity and improved uniformity. Real-time surveillance likewise enables instant restorative activities to be taken, decreasing waste and protecting against defective fibers from getting in the supply chain.

Additionally, this innovation promotes boosted data collection and analysis, offering understandings right into manufacturing patterns and prospective areas for improvement. Such data-driven decision-making empowers makers to maximize procedures and keep high criteria of top quality control.

Furthermore, real-time monitoring fosters a culture of continuous enhancement within the production environment. Employees are extra involved when they can see the impact of their operate in real-time, resulting in heightened accountability and a commitment to quality. In general, the application of real-time tracking systems in optical Fibre production equates to exceptional item quality and raised consumer fulfillment.

Effect On Manufacturing Performance

Executing optical Fibre Diameter analysers considerably improves manufacturing efficiency by simplifying the production process. These gadgets assist in continual monitoring of Fibre Diameter, allowing makers to identify inconsistencies in real-time. By recognizing incongruities immediately, assembly line can be changed promptly, lessening downtime and decreasing the possibility of producing defective items.

Additionally, the integration of these analysers right into the production operations makes it possible for far you can look here better resource allotment. With accurate Diameter dimensions, drivers can optimize product use, ensuring that sources are not squandered on problematic fibres. This accuracy likewise contributes to much less ditch and rework, ultimately lowering manufacturing costs.

The automation offered by optical Fibre Diameter analysers minimizes reliance on hands-on assessments, which are vulnerable and often lengthy to human mistake. Because of this, employees can focus on more tactical jobs, boosting total efficiency.

Furthermore, the information produced from these analysers can notify process improvements and help with far better decision-making. By examining fads in Fibre Diameter variants, manufacturers can apply aggressive procedures to enhance manufacturing methods and keep regular high quality. In recap, optical Fibre Diameter analysers play a vital duty in boosting production performance, causing better outcome and boosted success.

Study and Success Stories

Throughout numerous fields, study highlight the transformative impact of optical Fibre Diameter analysers on production processes. One popular instance is a leading telecoms business that faced obstacles with irregular Fibre sizes, bring about boosted being rejected rates. By incorporating an optical Fibre Diameter analyser, the business achieved real-time tracking of Fibre dimensions, leading to a 30% reduction in issues and substantial expense savings.

Moreover, a research organization concentrating on innovative materials made use of optical Fibre Diameter analysers to improve their experimental processes. The analyser's capability to provide comprehensive understandings right into Fibre consistency allowed the growth of cutting-edge products with enhanced performance qualities.

These success tales underscore the vital role of optical Fibre Diameter analysers in enhancing high quality control, improving production performance, and driving technology across diverse sectors.

Verdict

In verdict, the Optical Fibre Diameter Analyser plays an essential function in improving quality assurance within Fibre production. By offering specific, real-time measurements and promoting instant restorative actions, this modern technology substantially reduces variability and minimizes waste. The application of such advanced devices fosters a society of constant renovation and operational effectiveness, ultimately guaranteeing conformity with industry standards and maintaining competition. As from this source demonstrated via numerous see this here study, the analyser shows vital for accomplishing remarkable product top quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers allowed for strict high quality control, making sure that the created fibres fulfilled exacting sector standards.In verdict, the Optical Fibre Diameter Analyser plays a critical role in boosting high quality control within Fibre manufacturing.

Report this page